Max board size: 400*340mm

Min board size: 50*50mm

Feature:

GKG GSE

Economical automatic printing machine

Advanced up-view/down-view vision system, independently controlled and adjusted lighting, high-speed moving lens, accurate alignment of PCB and template, ensuring printing accuracy of ±0.025mm.

♦ High-precision servo motor drive and PC control to ensure the stability and precision of printing, unlimited image pattern recognition technology, with ±0.01mm repeat positioning accuracy.

♦ Suspension printing head with a specially designed high rigidity structure. The pressure, speed and stroke of the scraper are controlled by computer servo to maintain uniform and stable printing quality.

♦ Optional manual/automatic screen bottom cleaning function. Automatic, unassisted cleaning of the bottom surface of the stencil, programmable control of dry, wet or vacuum cleaning, cleaning intervals can be freely selected, can completely remove residual solder paste in the mesh, and ensure printing quality.

♦ Combined universal workbench, which can be set to place thimbles and vacuum nozzles according to the size of the PCB substrate, making clamping faster and easier.

♦ Multifunctional board handling device, which can automatically position and clamp PCB boards of various sizes and thicknesses, with movable magnetic thimbles, vacuum platform and vacuum box, which can effectively overcome board deformation and ensure uniform printing process.

♦ With "Windows XP" operation interface and rich software functions, it has a good man-machine dialogue environment, easy to operate, convenient, easy to learn and easy to use.

It has the function of fault self-diagnosis sound and light alarm and prompting the cause of the fault.

No matter single-sided or double-sided PCB substrate can work.

It can perfectly print pads with a pitch of 0.3mm.

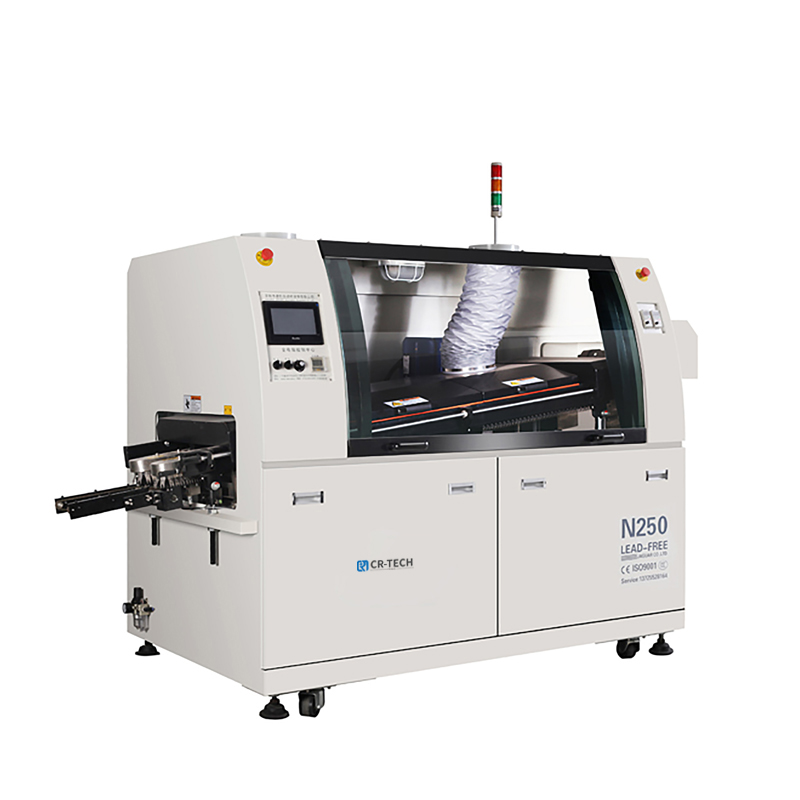

Image:

Specification:

Machine performance

Repeat position accuracy

±0.01mm

Print accuracy

±0.025mm

NCP-CT

7.5s

HCP-CT

19s/pcs

Process CT

5min

Change line CT

3min

Substrate processing parameter

Max board size

400*340mm, 530*340mm(option)

Min board size

50*50mm

Board thickness

0.4~6mm

Camera mechanical range

528*340mm

Max board weight

3kg

Board adge clearance

2.5mm

Board height

15mm

Transport speed

900±40mm

(Max) Transport speed

1500mm/s max

Transport direction

One stage

Transmission direction

Left to right

Right to left

In and out the same

Support system

Magnetic pn

Support block

Manual up-down table

Board damp

Manual top clamping

Side clamping

Printing parameters

Print speed

10-200mm/s

Printing pressure

0.5~10kg

Print mode

One/twice

Queegee type

Rubber, squeegee blade (angle 45/55/60)

Snap- off

0-20mm

Sanp speed

0-20mm/s

The template frame size

470*370mm-737*737mm (thickness 20-40mm)

Positioning mode of steel mesh

Manual positioning

Cleaning parameteres

Cleaning method

Dry, wet, vaccum, three modes

Cleaning system

Side drip type

Cleaning stroke

Automatic generation

Cleaning position

Post cleaning

Cleaning speed

10-200mm/s

Cleaning fluid consumption

Auto/Manually adjustable

Cleaning pater consumption

Auto/Manually adjustable

Vision parameters

CCD FOV

10*8mm

Camera type

130 thousand CCD digital camera

Camera system

Lock up/down optic structure

Camera cycle time

300ms

Fiducial mark types

Standard fiducial mark shape

Round, square, diamond, cross

Pad and profile

Mark size

0.5-5mm

Mark number

Max. 4pcs

Stay away number

Max. 1pc

Machine parameter

Power source

AC 220 ±10%, 50/60Hz 2.2KW

Air pressure

4~6kgf/cm²

Air consumption

~5L/min

Operating temperature

-20°C~+45°C

Working invironment humidity

30%-60%

Machine dimension (without flower light)

1152(L)*1362(W)*1460(H)mm

Machine weight

Appr 900kg

Equipment load bearing requirements

650kg/m²